Małgorzata JAWORSKA, Elżbieta SIKORA, Jan OGONOWSKI ? Institute of Chemistry and Organic Technology, University of Technology, Cracow, Poland

Abstract:

The aim of this work was the preparation and rheological characterization of o/w nanoemulsions stabilized by polysorbates, containing Crodamol PC as the oil phase. The formulations were prepared by phase inversion composition method. Measurements of the internal phase droplets size were carried out using Malvern Zetasizer apparatus. The rheological properties of the emulsions systems were studied by using Brookfield rheometer, Model – R/S Plus. The obtained results confirmed that the prepared nanoemulsions showed non-Newtonian, pseudo-plastic behavior.

Please cite as: CHEMIK 2013, 67, 2, 119-126

Introduction

The effectiveness of cosmetic products depends largely on their physicochemical form. A relatively new form of cosmetic products is nanoemulsions, liquid dispersion systems of internal phase particles size of 20 ? 500 nm. Particles of nanoemulsions are too small to scatter visible light, which makes them optically transparent or translucent. Due to its properties (a large interfacial surface area, low surface tension), nanoemulsions affect on an increase of their percutaneous absorption) [1÷ 7].

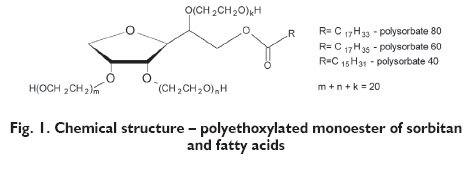

As a form of cosmetics they can relatively easily penetrate into the skin, exhibit a high degree of hydration and soften the skin and have a very good user properties (ease of spreading on the skin, no greasy feeling). Thanks to their structure they can also transport both hydrophilic and hydrophobic active substances to the skin. Polysorbates are polyethoxylated esters of sorbitol, sorbitans and isosorbide. A structure of polyethoxylated monoester of sorbitan shows Figure 1.

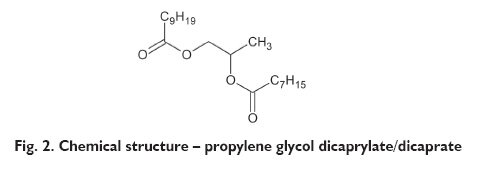

Polysorbates are a range of mild nonionic surfactants. They are excellent O/W emulsifier, solubilisers, wetting agents and dispersants. They offer many advantages over ionic surfactants such as soaps, including increased stability, formulating flexibility and wider compatibility. They can be widely used in personal care applications (O/W creams and lotions, sun protection products, antiperpisrants, colour cosmetics, etc.) thanks to their biocompatibility with the skin and biodegradability [8]. Crodamol PC is the propylene glycol diester of caprylic/capric acid (Fig. 2).

It offers several functional benefits with applications in a number of cosmetic and pharmaceutical products such the lipophilic vehicle, skin permeation enhancer, oxidatively stable, non-greasy emollient, good spreading agent, low viscosity products. Due its properties Crodamol PC is the popular cosmetics ingredient, applied in skin care products as an emollient, which is characterized by good user properties, e.g. easy spreading, no occlusive feeling [9].

The aim of this work was the preparation and rheological characterization of o/w nanoemulsions stabilized by polyethoxylated esters of sorbitol (polysorbates) containing Propylene Glycol Dicaprylate/Dicaprate (Crodamol PC?) as an oil phase. The effect of the concentration and the type of emulsifier on the rheological properties of the emulsions was studied.

Materials and methods

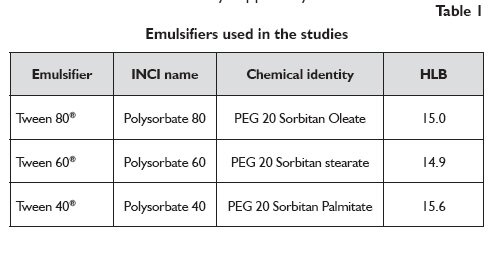

In the studies, to obtained stable emulsion, Polysorbates have been applied. Polysorbate is a group of non-ionic emulsifiers, with different HLB and the similar chemical nature (Tab. 1). The surfactants selection was made because of their good performance and lack of irritation and toxicity to the skin. Crodamol PC? (INCI: Propylene Glycol Dicaprylate / Dicaprate), was used as an oil phase. The aqueous phase was distilled water. Both, the emulsifiers and the Crodamol PC used in our studies were kindly supplied by Croda.

Formation of O/W nanoemulsions

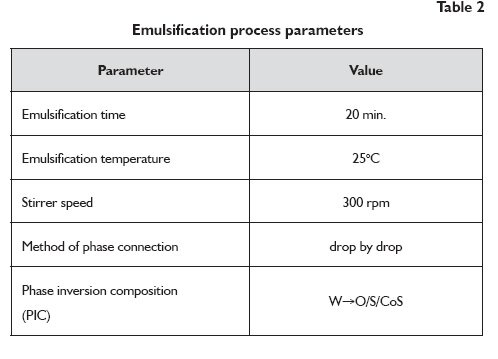

The emulsions systems were prepared by phase inversion method (PIC) by stepwise water (W) addition to the mixture of oil (O) and surfactant (S)/co-surfactant (CoS), at room temperature (25oC). The mixture was stirred using a magnetic stirrer, IKA C-MAG HS 7 equipped with speed control. The emulsification process parameters are shown in Table 2.

Assessment of rheological properties

Rheological properties of the emulsifier and the emulsions were studied using Brookfield Rheometr Model ? R / S-plus, equipped with a cone-plate type measuring system (cone C75-1, viscosity measurement range 9 to 60 000 mPas), at two temperatures: 25°C (298 K) and 37°C (310 K) which is close the human body temperature. The rheological studies were carried out with variable viscosity shear rate in the range of values from 1 to 1000 s-1.

Measurement of droplet size

The average internal phase droplet size of the obtained emulsions were measured by Dynamic Light Scattering (DLS) method, using Malvern Zetasizer Nano ZS apparatus , which measures particle size (range from 0.3 nm to 10 mm) by scattering photons from a sample and determine the change in diffracted light intensity [10]. Scattering angle was 173°.

Results and discussion

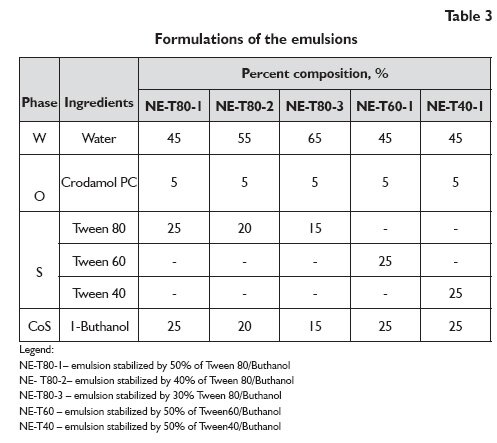

Five stable nanoemulsions were obtained as results of our work, their compositions are shown in Table 3. Notable is the fact that the emulsions can be obtained in the ambient temperature, the method does not require energy input.

Characterization of the emulsions

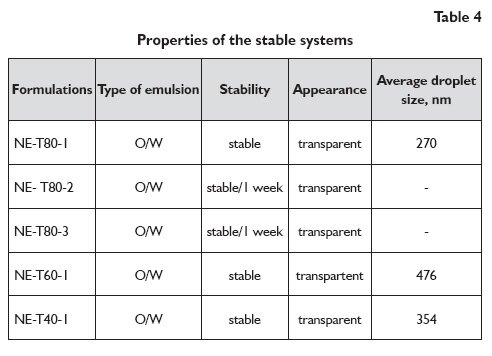

In the Table 4 and in Figure 3 are shown physicochemical properties of the obtained stable systems.

The data presented in Table 4 show that the stable, transparent, o/w nanoemulsion, containing as an oil phase Crodamol PC, could be obtained using Polysorbates as the emulsifiers. It should be noticed that the kind of used emulsifier influences on internal phase droplets size. The emulsion NE-T80-1, which is stabilized by Tween 80 is characterized by the smallest size of the dispersed phase droplets. Moreover, the obtained results showed that the ratio of oil phase to the surfactant mixture affects the properties of prepared emulsions.

Stability of nanoemulsions

The samples were stored, at ambient temperature, for 24 hours, 47 hours, one week and one month. During the time the stability of the formulations were assessed visually. The emulsion systems stabilized by the 50% addition of surfactant / co-surfactant mixture were transparent and stable. There was no phase separation observed, during the studies. Whereas systems with lower content of surfactant (NE-T80-2, NE-T80-3) was unstable after a period of 1 week. Moreover, all emulsions with 50% addition of surfactant / co-surfactant mixture (NE-T80-1, NE-T60-1 and NE-T40-1) were also stable at 370C (310,0 K). These nanoemulsion showed no change in clarity and phase behavior.

Rheological characterization

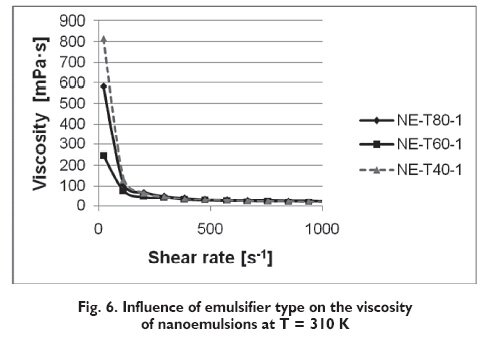

Emulsifiers used in the studies differed not only the hydrophiliclipophilic properties (Table 1, different values of HLB), but also had different rheological character. Ethoxylated sorbitan oleate (Polysorbate 80, HLB = 15) and ethoxylated sorbitan palmitate (Polysorbate 40, HLB = 15.6) exhibited Newtonian character, at 25 ° C. Their viscosity was constant in the studied range of shear rate (from 1 to 1000 s-1) and it was h1=360 mPa?s and h2=303 mPa?s, respectively. Whereas ethoxylated sorbitan stearate (Polysorbate 60) showed non-Newtonian behaviour. The decrease of viscosity with the increasing shear rate was observed in this case (e.g. for the shear rate g = 50 s-1 the viscosity was h3 =8840 mPas, and for the shear rate g = 100 s-1 the viscosity was h4 = 4480 mPas). Figures 4 ÷ 6 show the viscosity curves of obtained nanoemulsions.

Figure 4 shows that all nanoemulsions are characterized by pseudo-plastic behaviour. It is worth noting that the emulsion NE-T80-1 is characterized by the highest viscosity than the emulsion NE-T80-2 and NE-T80-3, it is probably due to the largest emulsifier (Tween 80) content (50%), (Tab. 3).

Data presented in Figure 5 shows that the system stabilized with Polysorbate 40 (NE-T40-1), an emulsifier with the highest HLB value (15.6) but the smallest viscosity of the used surfactants, has the highest viscosity. Contrary, the least viscous system was stabilized by ethoxylated sorbitan stearate (polysorbate 60), an emulsifier with the highest viscosity among the studied surfactants, characterized by the lowest HLB value (14.9). It can be concluded that the viscosity of the emulsifiers used in studies does not affect the rheological properties of the obtained emulsion. The viscosity of the obtained nanoemulsions depends on the hydrophilic-lipophilic properties of emulsifier, mainly. Systems with the higher viscosity were obtained using emulsifiers with the higher HLB value (the more hydrophilic character). This is probably related to the interaction at the interface emulsifier ? water phase.

All emulsions are non-Newtonian liquids also with pseudo-plastic rheological behaviour. Moreover NE-T40-1 emulsion, stabilized by an emulsifier with the highest HLB value (15,6), is characterized by the highest viscosity (Fig. 5). Perhaps, it is due to the interaction between oil phase and emulsifier.

Figure 6 shows that also in higher temperature nanoemulsions keep their pseudo-plastic rheological behaviour. NE-T40-1 emulsion is characterized by the highest viscosity and NE-T60-1 emulsion by the lowest value of viscosity as it was observed at 250 C (298 K) temperature. Figures 7 and 8 show flow curves of the study nanoemulsions. They also confirm pseudo-plastic character of the products.

The data presented in Figure 10 shows that the viscosity of all emulsion formulation decreased with the increase of temperature. That means that after application of the emulsions, during the contact with the skin, they would be easy to spread.

Conclusion

The following conclusions were found on the basis of studies:

? the obtained nanoemulsions are non-Newtonian liquids with pseudo-plastic rheological behaviour

? the kind and concentration of emulsifier influence on viscosity of the emulsion systems, the nanoemulsion stabilized by Polisorbate 40 ( an emulsifier with the highest HLB value) is characterized

by the highest viscosity

? with increase of the temperature the viscosity of the studied emulsions decreases, it can be helpful in their cosmetic applications.

Literature

1. Porras M., Solans C., Gonzalez C., Gutierrez J. M., Properties of waterin-oil (W/O) nano-emulsions prepared by a low-energy emulsification method, Colloids and Surfaces A:Physicochem.Eng.Aspects, 2008, 324, 181 ? 188

2. Kothekar S.C., Waghmare J.T., Momin SA, Rationalizing and Producing Nanoemulsions for Personal Care, Cosmetics&Toiletries, 2006, 7, 51 ? 56

3. Usón N., Garcia M.J., Solans C., Formation of water-in-oil (W/O) nano-emulsions in a water/mixed non-ionic surfactant/oil systems prepared by a low-energy emulsification method, Colloids and Surfaces A:Physicochem.Eng.Aspects, 2004, 250, 415 ? 421

4. Sadurni N., Solans C., Azemar N., Garcia-Celma M.J., Studies on the formation of O/W nano-emulsions, by low energy emulsification methods, suitable for pharmaceutical application,s European Journal of Pharmaceutical Sciences, , 2005, 26, 438 ? 445

5. Tadros T., Izquierdo P., Esquena J., Solans C., Formation and stability of nano-emulsions, Advances in Colloid and Interface Science, 2004, 108?109, 303 ? 318

6. Bouchemal K., Briancon S., Perrier E., Fessi H., Nano ? emulsion formulation using spontaneous emulsification: solvent, oil and surfactant optimisation, International Journal of Pharmaceutics, 2004, 280, 241 ? 251

7. Somasundaran P., Chakraborty S., Deo N., Somasundran T., Nanoencapsulation for Extraction and Release of Fragrance, Cosmetics&Toiletries,

8. 2006, 12, 47 ? 54

9. http://pceurope.crodadirect.com

10. http://health.crodadirect.com

11. Guglielmini G., Evaluating Droplet Size in Nanoemulsions from a Novel Emulsifier System, Cosmetics&Toiletries, 2006, 121(12), 67-72

Translation into English by the Author

Małgorzata JAWORSKA ? M.Sc., graduated from the Faculty of Chemical Engineering and Technology, Cracow University of Technology in 2008. Now she is a doctoral student at the Institute of Organic Chemistry and Technology of the Cracow University of Technology. She specializes in cosmetic technology, especially in nanoemulsions.

Elżbieta SIKORA ? Ph.D., (Eng), graduated and completed her doctoral degree at the Faculty of Chemical Engineering and Technology of the Cracow University of Technology. Currently she is employed as Assistant Professor on the Organic Technology and Refining Processes Chair. Scientific interests include low-tonnage organic technology, as well as obtaining, investigating the properties and application of natural raw materials in cosmetic products and household chemicals.

Jan OGONOWSKI ? Professor (Ph.D., Eng), head of the Department of Technology of Organic and Refinery Processes at the Institute of Organic Chemistry and Technology. Specialization: technology, organic catalysis, technology low tonnage products.