Radosław POMYKAŁA, Paulina ŁYKO ? AGH University of Science and Technology, Faculty of Mining and Geoengineering, Department of Environmental Engineering and Mineral Processing, Krakow, Poland

Please cite as: CHEMIK 2013, 67, 5, 454?461

Introduction

Renewable energy sources as a way to supplement and even to replace conventional fuels, is a hot topic since many years. Virtually any type of fossil fuel can suggest several alternatives to the alternatives. For virtually any type of fossil fuel, several ?green? substitutes can be suggested as the alternatives. Depending on the transient fashions, available technologies and above all legal regulations attention of professionals and public opinion is directed to the other kind of ?replacement? of fossil fuels. The interest in, however, is not always distributed in proportion to the real benefits and the possibility of obtaining a source of energy in Poland.

Keywords: Biogas, biomethane, CNG, municipal waste

The article focuses on biogas as a fuel highly prospective and large manufacturing potential, which until recently was known mainly as a supplementary source of electricity and heat produced in installations located in landfills or in waste water treatment plants. For several years, this situation has been systematically changed thanks to the construction a growing number of biogas plants mainly based on agricultural waste. So far, however, was not any industrial plant producing biogas for transport purposes ? as a replacement for CNG, although this trend seems to be more promising in the long run. Biomethane ? biogas with high methane content is considered to be an excellent substitute for natural gas. Such use of biogas is already very well known in many countries, including in Sweden, Germany and Austria. It is a renewable fuel, with major scope for production in Polish conditions. Moreover, the use of biomethane in transport allows extending the traditional advantages of methane fuel mainly concerning reductions in emissions (compared to traditional fuels) to such items as ?renewability?, the variety and availability of substrates and the ability to the use of troublesome waste.

All this makes he use of biomethane allows to achieve an excellent result ?well-to-wheel?, where the is calculated total emissions and the impact on the environment throughout the life cycle, from acquisition through production and logistics to fuel use. The answer to the question about market barriers of development of biogas market as a transport fuel can be begin and finish at the same time by the statement about the lack comprehensive support, or more carefully about an insufficient support in this area by the State. This would not be a big exaggeration due to the fact that practically every country in which this market has developed, existed or still there are a clear incentives from the central government and/or local government, which create a model of the market. Such response would not only be simplified and incomplete, but also would not inject anything to the discussion on how to improve the current state of affairs.

Therefore, it was decided to collect and highlight the most important, according to the authors, barriers and the prospects facing to the development of the biogas market in Poland, especially produced from organic waste as fuel in transport. Attention is paid mainly to the availability and type of substrates, purification and possible forms of biomethane distribution.

Biogas, biomethane ? definitions

In the current legislation in Poland can be found two existing definitions of biogas:

Biogas – gas derived from biomass, in particular from processing plant of animal or plant wastes, sewage treatment plants and landfills [2].

Agricultural biogas ? gaseous fuel produced by the anaerobic digestion of agricultural raw materials, agricultural by-products, liquid or solid animal waste, by-products or residues from the processing of agricultural products or forest biomass, with the exception of gas derived from raw materials originating from sewage treatment plants and landfills [3].

There is no defined concept of biomethane. However, this term is used to describe the biogas with high methane content. Such biogas is prepared in the direction of used as fuel for transport means and / or injection into the natural gas network. In addition, the other determining are used [4]:

? CBG ? (compressed biogas) ? implicitly high-methane biogas i.e. bio-methane)

? LBG (liquid biogas) ? high-methane liquefied biogas, or liquefied biomethane

? bioCNG (compressed natural gas) ? a mixture of natural gas and biomethane, usually arising as a result of the injection of of biomethane into the natural gas grid.

Production of biogas

Biogas is produced by anaerobic digestion process by the decomposition of organic matter. It can be produced on the basis of various types of substrates, including both organic wastes and products specially grown in this direction. The process of creating biogas requires certain conditions and to ensure the efficiency of production, they should be carefully established and respected, and the process optimized for properties acquired substrates. Simultaneously, however, they are possible to meet even without human interference, for example in landfill of municipal waste.

Introduction of the concept of agricultural biogas was probably primarily the task of the promotion of agricultural feedstock for biogas production and the creation of a dedicated system to use them also for the development of rural areas. It allowed to separate agricultural biogas plants, from pre-existing installations, which produced biogas based on sewage sludge in wastewater treatment plants, or which obtain biogas from municipal landfills. This made it possible to support the construction of ?new type? of the installations ? ?agricultural biogas plants? (currently listed in the register maintained by the energy companies of the Agricultural Market Agency is 25 and are built more). From the point of view the needs of agriculture, it is difficult to dispute the validity of this approach, especially in the context of the huge amount of agricultural wastes (especially manure), ideally suited for use towards the production of biogas.

As a result, primarily were built biogas plants based on their own wastes from animal husbandry (usually liquid manure) and energy crops silage (usually corn). The produced biogas there was (and still is today) used to produce electricity and heat ? utilized on site. This arrangement is highly financially beneficial for many reasons. First of all, it is coherent in terms of ownership and logistics, what allows limit to the minimum financial flows concerning for example the purchase of substrates, as well as dependence on third parties. It all adds up to low operating costs, high independence and relatively low operational risk, including possible changes in the law. However, only a small part of those interested in biogas production is able to meet the needs of the substrates. Together with the necessity to purchase biogas feedstock increasing costs and operational risk. One way to do this is to add other waste such as from distilling, dairy or slaughter. In such a situation at work here usually a ?negative cost? waste, i.e., the manufacturer pays for their utilization. Nevertheless, this applies only waste that fall within the definition of agricultural biogas substrates.

Meanwhile, in natural manner appears the possibility of management various types of waste that does not fit the definition of ?agricultural feedstock,? and their use may result in loss the status of ?agricultural biogas?. In this way, the market began to show signs of over-regulation, and primary preferences have become the tool for limiting or even discriminatory, some potential substrates commonly used in many European countries (e.g. Sweden, Germany) [5]. The situation was somewhat mitigated when it was discovered that it is possible to obtain a specific response from the Ministry of Economy, the clarification of the waste in question may or may not be considered as a substrate for the production of agricultural biogas. In this way it became possible use e.g. outdated food. According to representatives of Ministry of Economy, in addition to being prepared currently regulation (a set of three laws: Law Gas, Energy Law and the Law on renewable energy sources) will find a list of substrates, from which it will be possible to produce agricultural biogas. However, neither the present nor the future, regulations do not provide for the eligibility of the organic fraction of municipal solid waste, as a potential feedstock for the production of agricultural biogas. Just as catering waste, green waste such as grass from green urban areas, or sludge from municipal sewage treatment plants [6].

Biogas and municipal waste

Municipal waste and, more specifically, their organic fraction as many features that distinguish it from other types of organic waste ? actual or potential substrates for biogas production. The most important of these include:

? Uniformity of the formation: municipal waste are produced across the whole country, and the amount depends primarily on population and location: city / village. Wherein, more organic municipal waste is, traditionally, formed in the cities, because of the limited possibilities of their management by the producers

? The small effect of seasonality: this kind of waste is produced throughout the year in similar amounts, except for tourist resorts

? The variability of the composition and properties: composition and properties of organic waste is dependent on both the time (the contents of the individual components, especially in the short term may fluctuate), location, method of collection and segregation. Municipal waste can contain heavy metals and other contaminants

? Difficulties in obtaining: so far collection of organic waste focuses on the so-called. green waste. While the collection of domestic organic waste ( ?kitchen waste? ) and other food waste (e.g. from gastronomic points), so far limited to single pilot implementations. So far there are no examples of a universal and comprehensive application of this type of waste collection in Poland.

The necessity management of organic fraction of municipal waste arise straight from the legal requirements. Under the Act on maintaining cleanliness and order in the communities, responsibility for municipal waste management lies on local government now. In accordance with the Council Directive 1999/31/EC of 26 April 1999 [7] Poland is committed to reducing landfill mass of biodegradable municipal waste in compare to mass of waste generated in 1995: from 75% in 2010 by 50% in 2013, up to the 35% in 2020. The average annual generation of municipal waste is about 10 million Mg in Poland, of which the about 30?50% is organic waste (biodegradable) [8]. It is necessarily those waste, origin from vegetable or animal, still constitute a significant percentage of the total municipal solid waste deposited in landfills. Achieve these limits is one of the most important challenges faced by municipalities in this area [9].

This all means that there is a need for investment in treatment of municipal waste, organic fraction first. One possibility is fermentation in the direction of biogas production. Suitable for this purpose are, in particular, the waste with significant water content such as leftover food or past due products, but other than municipal waste. Prevalence of biogas production based on municipal waste requires, in addition treating them as valuable and cheap substrates, including the implementation of modern systems collection systems of organic waste, and increase the level of public awareness in terms of waste segregation. These wastes should primarily be selectively collected at the source. What brings with it the need for separate containers and vehicles for the collection, as well as the implementation of separate models of the same collection, mainly because of the short period of decomposition of such waste, especially in the summer months. The next step is to meet the requirements for the operation of a waste treatment facility, including pre-line separation and preparation of an appropriate mixture of substrates. And all the best on the area of the currently existing waste management facilities (to avoid the need for additional transportation of waste), while maintaining the highest standards of hygiene, including indoor air quality [10].These actions will sooner or later have to be implemented regardless of whether such waste will be directed to production of biogas, or processed in some other way. At this stage it is worth to consider the possibility of preparing solutions which not exclude, but support the use of organic fraction of municipal solid waste in a mixture of substrates for biogas production.

This would connect biogas plant directly to the waste management system, lowering its costs through the production of electricity or biomethane. This is an opportunity especially for cities. However, this requires a comprehensive approach to the problem, including not only the initiative from the local government, but also the support of the central administration, as well as friendly legal requirements.

Purification and upgrading (enrichment) of biogas

Biogas consists mainly of methane and carbon dioxide, but it also contains nitrogen, oxygen, water vapor and a variety of other compounds as impurities treated (Tab.1). The type and content of the individual components depend on both the type of substrate and the conditions of the fermentation process.

Regardless of whether the purpose of the biogas is the electricity production or biomethane, it is necessary to purification, for at least for removal of water vapor and hydrogen sulfide and other contaminants in particular these which can cause corrosion. Depending on the purification process, it may be required the additional step of desulfurization. To obtain biomethane of a quality comparable to the natural gas with high methane content, it is necessary further refinement (enrichment) of biogas, which comes down primarily to the removal of carbon dioxide.

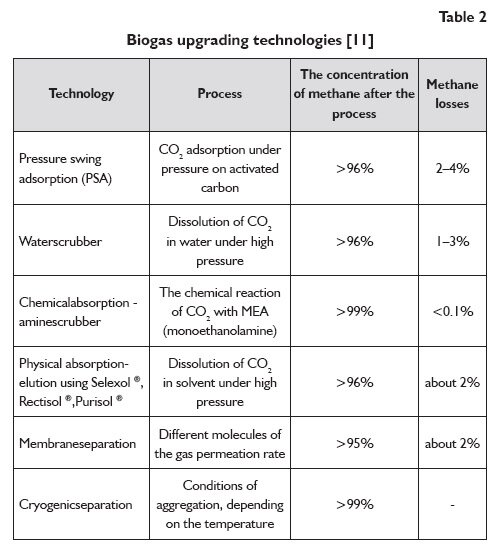

This is the most demanding process in terms of the technology, and the most expensive. There are many technologies of biogas to biomethane processing (Tab. 2). The most commonly used In Europe are pressure swing adsorption (PSA) and scrubber water [11]. None of the currently available technology is perfect, and each has advantages and disadvantages, so that any choice of biogas purification methods should be preceded by detailed analysis. Biogas can be upgraded into high-methane gas, low-methane gas, replaceable gas, or interchangeable gas. The difference between replaceable and interchangeable gas is that the former can be mixed with natural gas in any proportion, because it has the same characteristics. Interchangeable gas can be added only in limited quantities [12].To increase the calorific value of biomethane sometimes added to the LPG (liquefied petroleum gas).

The costs of construction and operation of purification and upgrading installation of biogas, can be a significant share of the total cost of producing biomethane. Their height is primarily determined by the size of purified biogas stream. Therefore, the cost per unit, based on the volume of biogas is greater the smaller the installation. Based on the current operating installations of its type in Europe, it can be estimated that the average investment cost of such installations is approximately 0.5?0.8 million euros for performance 250 Nm3 biogas/h (corresponding to a cogeneration unit with a capacity of about 500 kWel) to even 1.2 to 1.5 million Euros in the installation produced 1000 Nm3/h biogas (approx. 2 MWel respectively). The operating costs are directly related to the production of biomethane and conversely proportional to it, i.e. the smaller biogas production means the higher operating costs per unit of energy produced [11].

There will be no real extensive use of biogas (biomethane) as a fuel for transport in Poland, as long as the market does not propose a lowcost and effective systems for the purification and enrichment of biogas produced in different size (and power) of biogas plans. The current form of the draft Law on Renewable Energy Sources clearly favors the construction of micro and small installations (including biogas plants). Significant demand for low-cost biogas upgrading systems may concern smaller size of biogas sources.

In Poland, the possibility of the injection of biogas (biomethane) into the natural gas grid provides only for agricultural biogas. According to the Energy Law Act, it is possible to obtain a certificate of origin (the so-called ?brown? certificate) for production of agricultural biogas and injecting it into gas distribution network. The value of bronze certificates is the same as the green certificates for electricity generation from renewable energy sources. Gas system operator is obliged to collect agricultural biogas provided that meets certain quality parameters [13]. The gas to be injected to the transmission or distribution network must meet the quality parameters that have been defined in two standards:

? PN-C-04752:2002:2011 ? Natural gas. The quality of the gas transmission network

? PN-C-04753:2002:2011 ? Natural gas. The quality of the gas supplied.

For agricultural biogas injection into the gas grid was possible must be also met the conditions for connecting to the network, including in the field of measurement and control equipment. However still no examples of biogas injection in Poland, and the exact cost of the construction and exploitation of the injection point is unknown. Besides to injection into the gas grid, there is also the possibility of using biogas locally as fuel for fleet vehicles. In this case, the option is use biomethane of CNG quality as an independent or additional source of supply of filling station. Another possible solution is the production of biogas with higher methane content (but less than biomethane supplied to the network), for example, by mixing with natural gas, and then apply the mixture to supply the vehicles, specially prepared for this purpose. This last solution could be applied to entities that produce biogas, while they own fleet of vehicles [10]. So far, the entity intending to produce biogas and use it as fuel for transport, without the injection to the gas network, it cannot count on any additional preferences.

The benefits of using biomethane in transport

The main advantages of using biomethane as a fuel for transport are environmental values. Like the CNG, biomethane combustion accompanied by reduced emissions, including carbon monoxide, nitrogen oxides, and above all ? solid particles. Biomethane fueled vehicles are able to easily meet the requirements of Euro 5, in terms of pollution [14]. This is particularly important for traffic in the cities, especially threatened the formation of smog. In addition, biogas is a renewable fuel: emitted carbon dioxide was previously absorbed from the environment. Another very important aspect of the use of biomethane for transport is the possibility of its production from domestic feedstock in practically across the whole country. If additionally take into account the possibility of using for this purpose also waste, including difficult-to-management, will difficult to find other renewable fuel with so many advantages. The use of biomethane for transport purposes also is also supported by changes in EU legislation. The European Union has prepared a proposal for a new Directive [15] amending, among others RES Directive (i.e. 2009/28/EC), which lists the types of biomass that can be classified as twice and fourfold for the fulfillment of NIT (National Indicative Targets).Biofuels are to be released from one of the two components of excise duty related to CO2 emissions, and those made from wastes and residues to be considered twice to fill the NIT. Since recently biogas, is classified as liquid biofuels, in Poland, according to the law on biofuels and bio-components [16].

Summary

The production of biogas (biomethane) for the purposes of transport seems to be a natural consequence of the development of the biogas market. This is indicated by the experience of other European countries, and one of the most important factors here are possibility and efficiency of biogas energy utilization. Are already plenty companies engaged in construction and operation of biogas plants points to the fact that a key condition for the financial success of such investment is, in addition to providing a cheap source of feedstock, also use of thermal energy arising in a cogeneration plant. Transport of this type of energy is difficult and expensive. The cheapest is to use it in close connection of the installation, and so it is done in most existing units. All indications are that with the increasing number of constructed biogas plants will appear projects proposing production of biomethane.

Under current law, most likely is the injection to the natural gas network, high-methane agricultural biogas (biomethane) produced in the plant at least average power. It is the costs and uncertainty as to the size of the two most important elements of such a system: the installation of biogas up grading and the injection point, discourage potential investors. But this is not terra ignota? such systems are very numerous in the neighboring countries, including Germany and Sweden ? the leaders of the biogas market in Europe. It seems that the injection biogas into the network is only a matter of time, unless increase in the number of biogas plants will stopped systematic.

The situation is more difficult in the possibility of its use as a transport fuel because it is largely dependent on the development of the CNG market in Poland. This market is in the stagnating bordering with very slow development, for several years. As major barrier to its development NGV users consider a small number of gas filling points, while operators of the station ? a small number of vehicles powered by CNG. Out of this impasse may be method of ?escape forward? through the promotion of bio-methane, and by the way CNG, as economic fuels with a much lower emissions compared to diesel and gasoline. In particular useful in large urban areas, as a fuel for municipal vehicles, for passenger and freight transport, local delivery, etc. For this purpose, however, it is necessary to actively promote methane fuels and their support through actions at the local and central level. After years of waiting, on the preference for CNG from national authorities, should pay attention to local governments, which could support the development of this market, for example by favoring vehicles meeting strict emissions standards in public procurement, help in choosing a location for the new gas stations or encourage the construction of CNG distributors on already existed stations [17].

Undoubtedly, an important element in this regard is the development of ?bottom-up? ? increasing number of companies, especially in the SME sector is interested in building fleets of vehicles based on NGV. This is favored by both the ever-expanding range of vehicles, pre-designed to burn CNG, as well as wide offer of small gas compression stations, tailored to the needs of small customers. The most difficult to accomplish seems to be the development of biogas plants that use on a large scale organic fraction of municipal solid waste, mainly because it requires integrated actions at different levels and areas. On the other hand, foreign examples show that the production of biogas, also as a fuel for transport, as part of a comprehensive municipal waste management is a viable and advantage option, especially for municipalities [5].

Literature

1. Rogulska M. Jazda na biogazie Czysta Energia 2010, 12 (112), 25?27.

2. Rozporządzenie Ministra Gospodarki z dnia 14 sierpnia 2008 r. w sprawie szczegółowego zakresu obowiązków uzyskania i przedstawienia do umorzenia świadectw pochodzenia, uiszczenia opłaty zastępczej, zakupu energii elektrycznej i ciepła wytworzonych w odnawialnych źródłach energii oraz obowiązku potwierdzania danych dotyczących ilości energii elektrycznej wytworzonej w odnawialnym źródle energii (Dz.U. 2008 nr 156 poz. 969).

3. Ustawa z dnia 10 kwietnia 1997 r. ? Prawo energetyczne (Dz.U. 1997 nr 54 poz. 348).

4. Wodołażski A., Rejman-Burzyńska A., Metan z biogazu ? nowe paliwo dla pojazdów samochodowych , Czysta Eenrgia 2011, 7?8, 23?24

5. Smerkowska M. Biogaz z odpadów ? szwedzki model inspiracją dla polskich miast,

6. Czysta Energia 2012, 9(133), 28?31.

7. Papajewska Magdalena, Proces inwestycyjny w biogazownie krok po kroku V edycja Konferencji ?BIOGAZ ? praktyczne aspekty inwestycji w zieloną energię? 25 października 2011r., Warszawa.

8. Rocznik Ochrony Środowiska 2010, ww.stat.gov.pl , 20.01.2013.

9. Plan Gospodarki Odpadami Województwa Małopolskiego 2012, www. malopolskie.pl, 15.02.2013,

10. Dyrektywa Rady 1999/31/WE z dnia 26 kwietnia 1999 r.w sprawie składowania odpadów

11. Kuczyńska I., Pomykała R.: Biogaz z odpadów paliwem dla transportu ? bariery i perspektywy, Energetyka gazowa 2012, 4, 34?39.

12. E Lachwacka M., Technologie uszlachetniania biogazu do jakości gazu ziemnego, Czysta Energia 2009, 12, 26?27.

13. Mroczkowski P., Seiffert M., Oczyszczanie i zatłaczanie biogazu na przykładzie

14. Niemiec. Możliwości wdrożenia technologii w Polsce, 2011, www.cire. pl,14.12.2012

15. Smerkowska B. Ekonomiczne aspekty wytwarzania biogazu w celu wprowadzenia do sieci gazowej, Info Day projektu GreenGasGrids, 24 kwietnia 2012,

16. Fuksa D., Ciszyńska E., Łyko P.: Pozytywne aspekty wykorzystania biogazuna przykładzie transportu, Materiały konferencyjne IZIP ? Zakopane 2012, 475?485

17. Dyrektywa Parlamentu Europejskiego I Rady 2009/30/WE z dnia 23 kwietnia 2009 r., zmieniająca dyrektywę 98/70/WE .

18. Ustawa z dnia 25 sierpnia 2006 r. O biokomponentach i biopaliwach ciekłych

19. Dz. U. Nr 169, poz. 1199, z późn. zm.

20. Rogulska M. Biopaliwa w transporcie publicznym na przykładzie miasta, Czysta Energia, 2011, 8, 25?26

Radoslaw POMYKALA ? Ph.D., (Eng), is working as an Assistant Professor at AGH University of Science and Technology, Faculty of Mining and Geoengineering, in Department of Environmental Engineering and Mineral Processing. His main fields of interests are issues of disposal and utilization of various types of waste. He is the author or co-author of over 35 articles and monographs. Currently coordinates in Poland the Biomaster project, financed by the Intelligent Energy Europe program, concerning of the use of biomethane – biogas with high methane content, as fuel in transport. e-mail: ; phone:

Paulina ŁYKO ? M.Sc., is a graduate of the AGH University of Science and Technology in Krakow (Faculty of Mining and Geoengineering, 2010) She completed postgraduate studies in Renewable Energy. She is currently a PhD student in the Department of Environmental Engineering and Materials Processing. Since 2011, she has been working in a team realizing the BIOMASTER project funded by IEE Program, which is coordinated in Poland by AGH-UST. e-mail: ; phone: