Ryszard WASILEWSKI ? Institute for Chemical Processing of Coal (IChPW), Zabrze, Poland; Tomasz SIUDYGA ? Silesian University of Technology, Gliwice, Poland

Please cite as: CHEMIK 2013, 67, 5, 435?445

Introduction

Widespread application of plastic is accompanied by negative effect of wastes production constituting a serious environmental problem. An important role in this area is played by the introduction, in recent years, in the countries of the European Union stronger restrictions on the disposal of organic waste and the requirement to achieve high levels of recovery and recycling of certain waste groups, in which waste plastics constitute a large part. Waste packages, as well as building and automotive wastes are the main sources of plastics wastes (Fig. 1).

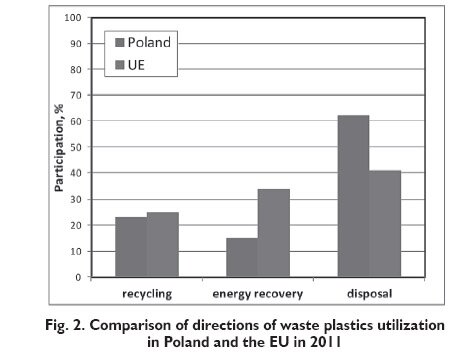

Waste plastics at first should be recycled by mechanical or chemical recycling and when it is not cost-effective utilized for energy recovery. According to Plastics Europe Foundation 25.1 mln Mg of plastic waste were produced in 2011 [1], 6.3 mln Mg of these wastes were recycled and 8.6 mln Mg was utilized for energy recovery. The remaining part of the waste plastics was disposed at landfills. Only about 8% of plastic waste is recovered as a result of selective collection from the stream of municipal wastes in Poland [2]. Approximately 23% of these wastes are recycled and there is a systematic increase in the field for several years. Another 15% is utilized for energy recovery through the production of solid recovered fuels [1]. Figure 2 shows the differences in directions of waste plastics utilization in Poland and the EU in 2011.

Results shown in the graph indicate that energy recovery from waste plastics in other EU countries play a much greater role in comparison with Poland. In some countries, such as Switzerland, Denmark, Sweden, Belgium, Austria and Netherlands participation of energy recovery even exceeded level of 60% [1].

Energy recovery from waste plastics is mostly realized in waste incineration plants and cement kilns. There are also performed attempts to co-combustion of waste plastics in power plants using fluidised bed boilers and pulverized-fuel boilers [3÷6]. In some countries, such as Japan and Germany, the waste plastics are used in metallurgical processes [7, 8]. The paper presents the possibility of energy recovery of waste plastics and organizational and legal aspects of this process.

Energetic qualities of waste plastics

Plastics have a very high heating value, often exceeding 40 MJ/kg. It results from a high content of carbon and hydrogen, and low ash content. Higher heating value is observed only for natural gas (48 MJ/kg), and comparable for heating oil (about 43 MJ/kg). Whereas, coal has a heating value of about 28 MJ/kg, and paper and wood approximately 15?16 MJ/kg. Such high heating value of plastics causes that plastic wastes can partially substitute fossil fuels, so that in direct way saves natural resources. Therefore, in case when recycling leading to the recovery of the material can?t be carried out due to technical limitations or lack of economic viability ? energy recovery is definitely the best way to recover the value of waste plastics.

Large part of the plastic fraction from municipal wastes separation plant is used, among others, for energy recovery [3, 4]. Table 1 shows the properties of these materials, in comparison with bituminous coal.

The differences between the values of particular parameters for the pure substances and recovered from the wastes resulting from using in commercial plastics a number of additives, such as dyes, fillers or others substances improving their properties, as well as contamination by other materials. Plastics presented in Table 1, of course, do not include all components that can exist when the possibility of their use as potential combustible substances is considered.

The possible emission of harmful compounds such as chlorine, hydrogen chloride, phosgene, benzene and its derivatives, ammonia, and hydrogen cyanide, as well as formic acid, formaldehyde, phenol, and polychlorinated dioxins and furans is one of the main objection at considerations on energetic use of waste plastics. Significant content of halogens and nitrogen in the composition of certain polymers provides to such danger. Hence, because of the risk of emissions during combustion, the most dangerous polymers are poly(vinyl chloride) PVC, polyurethane PUR, poly(methyl methacrylate) PMMA, polyamide PA, and phenol-formaldehyde resin PF [9]. These materials require special attention in the selection of combustion technology. Limitation of emissions is accomplished by reducing PVC content in treated waste and introduction of complex exhaust gas cleaning systems. This solution, however, is associated with a significant increase in costs, which are difficult to clear estimate because of the multitude of applicable technologies and a variety of processed waste.

Generally, the energy recovery from plastic waste can be carried out directly by the incineration of municipal waste containing plastic fraction or as a substitute of solid fuel (so called solid recovered fuels). It is also possible intermediate variant of thermo-chemical processing of waste plastics into substitute of liquid fuels. Variant of the direct use of waste plastics to energy recovery requires the fulfillment of formal and legal requirements and technical specifications for waste incineration process.

Waste incineration

In accordance with the regulations in the Act on waste dated 14 December 2012 (Dz. U. 2013, pos. 21), waste incineration may be carried out only in incineration or co-incineration plants.

Waste incineration plant according to this Act means a plant, or a part of thereof, designated to thermal conversion of waste, with or without recovery of the energy produced, covering the installations and equipment used to carry out a thermal process of conversion of waste along with the purification of waste gas and introduction of thereof into the atmosphere, control, steering and monitoring of processes and the installations connected with the acceptance, initial processing and storing of wastes and installations connected with storing and processing of substances obtained as a result of incinerating and cleaning of waste gas.

Whereas co-incineration plant means a plant, or a part of thereof, the main objective of which is producing energy or products in which, along with fuels wastes are thermally converted in order to recover energy included therein or in order to dispose them. Hence, cement and power plants using wastes as a source of energy beside main fuel are co-incineration plants. Requirements for incineration and coincineration plants are generally the same. Act on waste requires that waste incineration and co-incineration plants should be designed, constructed, equipped and operated to achieve a level of incineration, in which amount and harmfulness of waste and other emissions from thermal treatment (including residues from the process) will be as small as possible. Specific requirements in this area are defined in the Regulation of the Minister of Economy on requirements for waste incineration process dated 21 March 2002 (Dz. U. No. 37, pos. 339, as amended).

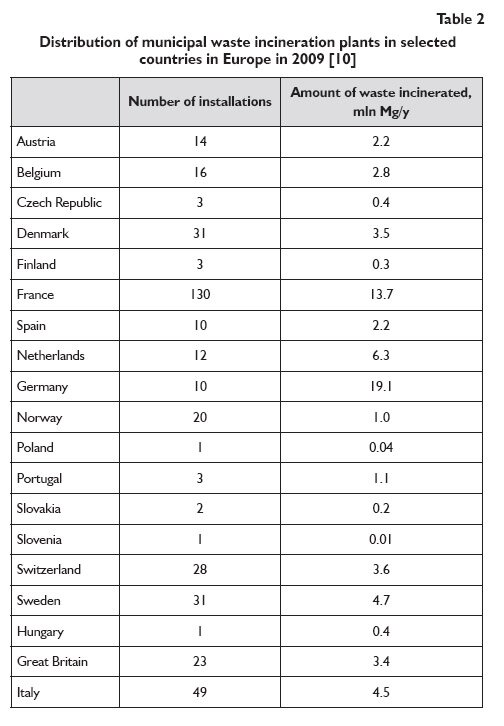

The distribution of municipal waste incineration plants in selected countries in Europe with the estimated amount of thermally processed non-hazardous waste is shown in Table 2. Almost all large waste incineration plants constructed in Europe in recent years, are stokerfired installations. In ?90s fluidized bed installations seemed to be alternative systems, but necessity of pre-crushing of waste caused resignation from this technology. In ?90s fluidized bed installations seemed to be alternative systems in this area, but difficulties with pre-crushing of waste and associated energy consumption causes these technologies are characterized by lower energy efficiency rate in comparison with stoker-fired installations. The most popular in this area are installations with step grate (Steinmüller, Nielle, Martin, Von Roll, V?lund and Krüger) and with cylindrical grate (e.g. Deutsche Babcock Anlagen).

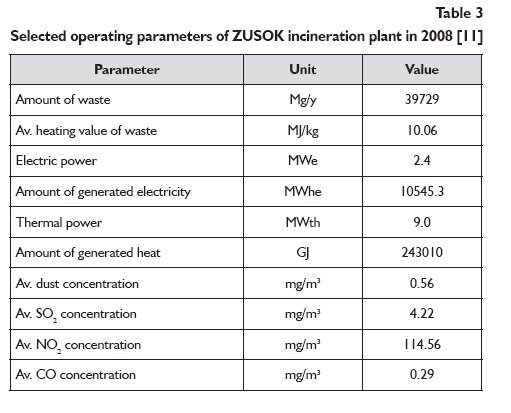

Currently the only one plant of its kind in Poland is located in Warsaw. It?s Zakład Unieszkodliwiania Stałych Odpadów Komunalnych (ZUSOK), which started in 2001. The main parameters of this installation are presented in Table 3.

The program for building of municipal waste incineration plants in Poland was created in 2007 and included so-called indicative list of the Ministry of Regional Development under Operational Programme ?Infrastructure and Environment?. The program originally assumed construction of 12 municipal waste incineration plants in Szczecin, Koszalin, Poznań, Gdańsk, Olsztyn, Białystok, Bydgoszcz, Łódź, Warsaw, Kraków and 2 plants in Silesia. The total efficiency of these installations had to reach about 2.4 mln Mg per year [12]

At this moment only objects in Szczecin, Poznań, Bydgoszcz, Kraków and Białystok are on the essential steps of implementation. There is also the environmental decision for location in Konin, not included on original list. The total capacity of these 6 installations should equal about 1.1 mln Mg per year, and they are planned to start at the end of 2015. The largest planned installation is built in Poznań and its yield will amount 220 000 Mg per year. The investment costs for this plant are estimated at PLN 725 million. [13]. There are also a number of initiatives to build regional municipal waste incineration plants, such as in Tarnów, Chrzanów, Jastrzębie Zdrój, Rzeszów, Gorlice, Włocławek, Gdynia, Hrubieszów and Chodzież.

The total capacity of these installations seem to be too small in the context of the requirements of the ?landfill directive? (1999/31/EC), according to which entering the European Union, Poland has committed itself to 50% reduction of landfilled biodegradable wastes in 2013. In addition, in 2020 we should achieve another, 65% level of reduction of biodegradable waste coming to the landfills. It should also be noted that the European Commission plans on 2025 years a complete prohibition on landfill of biodegradable municipal waste, which increases the importance of investment in this area.

Required annual levels of recovery and recycling for packaging and post-consumer wastes are regulated by Regulation of the Minister of Environment on the annual levels of recovery and recycling for packaging and post-consumer wastes dated 14 June 2007. They are contained in the Annex to this regulation. It has to be processed 60% of the above waste to 2014 in Poland on the basis of signed Accession Treaty. At the same time 55% of packaging waste should be recycled. It is also assumed that for this year the level of recycling of packaging plastics will be at least 22.5%, which means that it reduces the amount available for energy recovery processes.

Waste plastics as a component of solid recovered fuels

High heating value of polymer waste causes that, they are often mixed with other wastes, such as paper, textiles, waste wood or tires and processed on ?alternative fuels? [3, 4]. Production of alternative fuels from wastes is often indicated as one of the fundamental elements of an integrated waste management system. Table 4 shows examples of compositions of alternative solid fuels from selected European installations.

The presented data show that the composition of solid alternative fuels produced in different plants can be highly variable. This is due to both local access to raw materials, as well as the requirements used by the customers. It has also considerable technological arrangement of the production, which is not standardized.

Production of alternative fuels in the EU countries is steadily increasing. The largest producers of SRF in the EU are Germany, Sweden and Italy. SRF production in Germany in the years 2005÷2008 increased from 2 to more than 5 mln Mg per year [14]. This trend is also observed in Poland. According to data from the Central Inspectorate for Environmental Protection production of solid recovered fuels in Poland in 2011 reached level of almost 1 mln Mg. The entire stream of this fuels was used in the cement industry. According to the Association of Cement Producers ? potential fuel consumption in the cement industry is forecast at about 1.2?1.5 mln Mg per year. So the SRF supply will soon satisfy demand in this sector. Analysis of Regional Waste Management Plans, which were amended in 2012, showed more than 100 installations of solid recovery fuels production in Poland at the end of 2010 [15]. Some of them had the capacity of 100 000 Mg per year. Steadily growing interest in using of wastes as a fuel, created in the European Union need to develop a coherent and universal system of classification of these fuels. These tasks have been undertaken by the European Committee for Standardization (CEN).

Developed by CEN classification and quality system of fuels produced from wastes for which name of SRF was adopted (Solid Recovered Fuels) allows to an unambiguous classification of fuel to specific classes and very detailed specification of the physicochemical properties. This allows to obtain reliable information on the quality of the material and choice of fuel for the guaranteed quality that fulfills technical requirements of a particular installation for operators of installations in which solid recovered fuels may be used [16÷18]. Considering the possibility of waste polymers as a component of solid recovered fuel it has to be pointed out that the high content of plastics influences on the mechanism of combustion of these fuels.

Solid fuel combustion occurs in four main stages including:

? heating of particles

? degasification/pyrolysis to carbonizate production

? ignition of flammable components

? combustion of carbonizate.

In practice, heating of the particles and the degassing occur simultaneously. Carbonizate is generally produced as an intermediate product in the process of combustion of the fuel after its heating and degassing. Ignition of heterogeneous fuels may be heterogeneous or homogeneous process with the influence between phases: gas/gas, gas/ liquid and/or gas/solid. Possibility of individual interaction depends on the fraction composition of alternative fuel. Figure 3 shows a diagram of the possible paths of the combustion process for the different fuel fractions, distinguishing three or four stages. Plastics fraction produces no carbonizate (except PVC), so there is no carbonizate combustion stage. Heated plastics pass into the liquid phase before the ignition of gas phase. Combustion of other fractions in fuels obtained from wastes occurs in four steps [19].

Reducing of PVC content is very important question in using waste plastic for production of solid recovered fuels, despite its high heating value, because of the risk of corrosion and emission. Receivers of fuels from wastes generally establish the requirements for the chlorine content in the fuel (usually <1%). Poly(vinyl chloride), due to the common use, is one of the main component of waste plastics and is responsible for high levels of chlorine in the waste fuels. It should be noted, however, that currently there is no possibility to separate of this material in automatic sorting installations. Assuming that the average share of waste plastics in the SRF produced in Poland ranges between 20?30%, it can be assumed that about 200?300 000 Mg of this wastes is used to SRF production.

Legal status relating to production and utilization of SRF

It is presented the most important formal, legal and technical regulations already applicable (January 2013) for the production and utilization of solid recovered fuels. Note: for the purposes of this study it was assumed that the term ?solid recovered fuel? is synonymous with the term ?alternative fuel? because this terminology is used in the existing legislation.

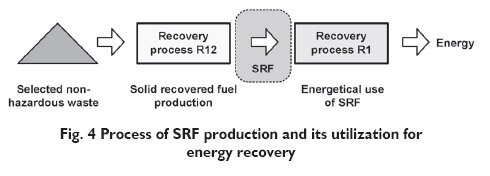

The current legislative regulations treat alternative fuel produced from wastes as ?waste?. The term ?alternative fuel? is introduced in the Regulation of the Minister of Environment on waste catalog dated 27 September 2001. (Dz. U. 2001, No. 112, pos. 1206). It distinguishes category of combustible wastes, in parentheses describing them as ?alternative fuels? (code 19 12 10). It should be noted that these are non-hazardous waste. In accordance with the Act on waste dated 14 December 2012 (Dz. U. 2013, No.0, pos. 21), the production of ?alternative fuels? is activity relating to recovery in the process R12 Exchange of wastes for submission to any of the processes specified in R1-R11 ? according to Annex 1 of the Act). However, the use of alternative fuels is a process of recovery R1 (using principally as a fuel or other means to generate energy ? according to Annex 1 to the Act). Process of SRF production and utilization is schematically shown in Figure 4.

Activity in the field of recovery in process R15 is not covered by the requirement to obtain an integrated permission. In accordance with the new Act on wastes in relation to mixed municipal waste, residual after waste sorting process, mechanical or biological treatment of waste destined for landfill and green waste understood as municipal waste, which are parts of plants from maintenance of green areas, gardens and parks will existed the collection and processing of waste in the region, defined in the regional waste management plans. The exception to this rule is the situation in which ?the installation for replacement? for municipal waste management is designated outside the region.

It should be noted that according to existing legislation ? installations of production of solid recovered fuels are not included in so-called ?regional installations?, which is a serious difficulty to access to raw materials.

Process of co-combustion of the alternative fuel (code 19 12 10) with fossil fuels such as coals is the process of incineration of nonhazardous waste and industrial installation in which this process occurs is a co-incineration plant. The installation, in which the co-incineration process can be realized must comply relevant formal, legal and technical requirements. Among the above-mentioned regulations, from the point of view technical requirements for co-combustion of waste most important are:

? Regulation of the Minister of Economy on the requirements for the process of thermal treatment of wastes dated 21 March 2002 (Dz. U. No. 37, pos. 339, as amended)

? Regulation of the Minister of Environment on the requirements for emission measurements and measurements of consumed water dated 4 November 2008 (Dz. U. No. 206, pos.1291)

? Regulation of the Minister of Environment on emission standards from installations dated 22 April 2011 (Dz. U. No. 95, pos.558).

Waste plastics processing towards the liquid components of motor and heating fuels

Chemical recycling of waste polyolefins towards the fuel fraction with trading symbol KTS-F (24.66.32?90.00 according to PKWiU classification) was developed in Poland to the end of 2006. The product was obtained in the process of thermal or thermal-catalytic decomposition of polyolefins in two variants: as a co-pyrolysis with technological oils [20, 21] or in ?oil-free? version [22]. Broad hydrocarbon fraction was subjected to distillation with the separation of the gasoline (<200°C) and diesel oil fraction (200?350°C) and then subjected to the process of hydrogen processing in order to give properties corresponding to the quality requirements for particular categories of fuels. In the largest plants operating on the basis of the version from paraffin oil (Agrob-Eco Ltd., Zabrze, Grupa LOTOSJasło SA) it was used only15?25% agglomerates from polyolefins in feedstock. The process was carried out for maximizing the content of the fraction corresponding to the diesel oil (~ 50?55% in relation to the amount of polymer-oil feedstock). In the case of technologies implementing co-pyrolysis of polyolefins with oils, product with a lower content of unsaturated compounds is obtained ? in the case of the analyzed technology it equals 10?25%. It means that this value is close to the quality requirements for the appropriate fractions (e.g. content of unsaturated compounds must not exceed 18% v/v in gasoline). Significant increase of the sulfur content in liquid products is main disadvantage to the introduction of paraffin oil to polyolefin feedstock ? it even reaches the value of 0.3?0.5% in Agrob-Eko Ltd, while in the case of ?oil-free? technologies it is usually not more than 0.1% [23].

It should be noted that this method of polymer waste management (generally only polyolefines) allows you to convert them into a product that ceases to be waste and can be included in the flow of raw materials for the production of liquid motor and heating fuels. Therefore, its further use is not associated with the requirements for thermal processing of wastes. Due to the high cost of manufacturing the product process was deficit, and the positive financial effect was obtained on the basis of Regulation of the Minister of Finance on the excise tax relief (Dz.U. No. 279, pos.2763). After 1st January 2007 with the liquidation of excise tax relief activity of this industry almost completely ceased.

It is worth mentioning that development of this method of polyolefins recycling based on the achievement of the national academic institutions (mainly Silesian and Wrocław University of Technology) and due to their close and successful cooperation with industry. Despite this, however, cases of lack of respect for intellectual rights was observed ? such as the cases of patent infringements by Refinery Jasło SA (in one case, opposition of refinery rejected by NSA).

Summary

Energetic qualities of waste plastics tend to use them as components of solid fuels manufactured from waste. The presence of plastic in the waste fuels influences on the combustion process, and may also cause the emission of harmful pollutants. It is important to note that energy recovery from solid recovered fuels is the process of waste incineration and in this case relevant formal, legal and technical requirements have to be applied. There are much less limitations for energetic use of liquid fuels produced by thermo-chemical processing of waste plastics.

Taking into account all the possibilities of waste plastics recovery the most favorable combination should be considered. The chosen option should take into account the case-specific available options for collecting and sorting of wastes, the demand for regranulate, raw materials and fuel. Under the current waste management hierarchy ? only after exhaustion of recycling due to technical or economic reasons ? plastic waste should be directed to energy recovery.

Low costs of pre-treatment of waste before energy recovery process is the main advantage of incineration which determine the cost-effectiveness of the process and its competitiveness in comparison with other waste management methods. It is usually measured by energy efficiency rate, which is the most favorable for stoker-fired installations. The difficulties with pre-crushing of waste and associated energy consumption (as in the case of fluidized bed installations) reduce value of this indicator. For the same reason other methods for waste processing into fuels (such as the production of liquid fuels from waste in thermal decomposition processes) has not found wide application.

Literature

1. Tworzywa sztuczne ? Fakty 2012, Analiza produkcji, zapotrzebowania oraz odzysku tworzyw sztucznych w Europie w roku 2011 (www. plasticseurope. com).

2. Rocznik statystyczny GUS. 2012.

3. Wandrasz J.W., Wandrasz A.J.: Paliwa formowane. Biopaliwa i paliwa z odpadów w procesach termicznych, Wyd. Seidel-Przywecki? Sp. z o.o., Warszawa, 2006.

4. Refuse derived fuel, current practice and perspectives ? Final Report, European Commission ? Directorate General Environment, 2003.

5. Campbell P.E., McCahey S., Williams B. C., Beekes M.L.: Coal and plastic waste in a PF boiler, Energy Policy, 2000, 28,. 223?229.

6. Boavida D., Abelha P., Gulyurtlu I., Cabrita I.: Co-combustion of coal and non-recyclable paper and plastic waste in a fluidised bed reactor, Fuel, 2003, 82, .

7. Nomura S., Kato K.: Basic study on separate charge of coal and waste plastics in coke oven chamber, Fuel, 2005, 84, 429?434.

8. Sobolewski A., Wasielewski. R.: ?Wykorzystanie odpadowych tworzyw sztucznych w procesie wielkopiecowym, CHEMIK, 2006, 4, 221?225.

9. Tworzywa sztuczne. Poradnik.: WNT Warszawa, wydanie V, 2000.

10. www.cewep.eu

11. Pająk T.: ZUSOK ? ochrona klimatu, źródło energii, VI Forum Operatorów Systemów i Odbiorców Energii i Paliw ?Bezpieczeństwo energetyczne a nowe kierunki wytwarzania i wykorzystania energii w Warszawie?, 16 października 2009 r., Warszawa

12. Wielgosiński G.: Wybór technologii termicznego przekształcania odpadów komunalnych, Nowa Energia, nr 1, 2012.

13. http://www.waste-management-world.com/articles/2013/04/sita-wasteto- energy-plant-largest-ppp-for-poland.html?cmpid=EnlWMW_Weekly- April122013.

14. www.erfo.info

15. Perspektywy wykorzystania stałych paliw wtórnych (SPW) do spalania w sektorach innych niż cementowy oraz wykorzystania odpadów tworzyw sztucznych, Sprawozdanie IChPW, Zabrze, 2012 (not published)

16. Sobolewski A., Wasielewski R., Stelmach S.: ?Wykorzystanie stałych paliw wtórnych w energetyce?, Polityka Energetyczna, 2007, 2, 379?390.

17. Van Tubergen J., Glorius T., Waeyenbergh E.: Classification of Solid Recovered Fuels, ORFA, 2005.

18. Wasielewski R., Stelmach S., Sobolewski A.: Wytwarzanie i wykorzystanie stałych paliw wtórnych, CHEMIK, 2011

19. prCEN/TR 15716 Solid recovered fuels ? Determination of combustion behaviour.

20. Praca zbiorowa pod red. J. Kijeńskiego, A.K. Błędzkiego i R. Jeziórskiej: Odzysk i recykling materiałów polimerowych, PWN, Warszawa, 2011.

21. Mianowski A., Kałyniak P., Siudyga T.: Diesel fuel from waste plastics, 5th IDENTIPLAST 2005, the Biennal Conference on the Recycling and Recovery of Plastics: Indentifying the Opportunities for Plastics Recovery, 18?19.04.2005, Bruksela.

22. Walendziewski J.: Termiczne przetwarzanie odpadowych poliolefin, Chemia Przemysłowa, 2005, 1,.22.

23. Siudyga T., Mianowski A.: Termiczny rozkład odpadów poliolefinowych z perspektywy badań laboratoryjnych i przemysłowego wykorzystania, Zeszyty Naukowe Wydziału Budownictwa i Inżynierii Środowiska Politechniki Koszalińskiej, 2007, 23, 373.

Translation into English by the Author

Ryszard WASIELEWSKI, ? Ph.D., (Eng), graduated from the Faculty of Chemical Technology and Engineering at the Silesian University of Technology in Gliwice in 1980. He also underwent postgraduate studies on waste management at the Faculty of Environmental Engineering and Energy at the same university (2000) and acquired I degree of engineering specialisation on Environmental Protection (2001). In 2012, he completed his doctoral studies, with the honours degree, in the Faculty of Environmental Engineering and Energy at the Silesian University of Technology. He is the laureate of a few international and local prizes for technological solutions in the field of environmental protection, among others: EUREKA Brussels (1992), IENA (Norymberga) (1998), MTWiI Warsaw (2010), EXPOCHEM Katowice (2011). He currently works in the Institute for Chemical Processing of Coal in Zabrze and makes specialisation in the field of thermal methods of coal and waste processing. He is the author and co-author of 8 chapters in monographs, 122 articles in the scientific and technology press and 68 papers and posters presented at domestic and international conferences. e-mail: ; phone:

Tomasz SIUDYGA ? Ph.D., graduated from the Faculty of Chemistry at the Maria Curie-Skłodowska University in Lublin. In 2006, he completed his Ph.D. degree in technical science at the Silesian University of Technology, Faculty of Chemistry. He is the laureate of a few international and local prizes for technological solutions in the field of chemical industry and environmental protection, among others Międzynarodowa Wystawa Wynalazków i Innowacji in Warsaw (International Warsaw Invention & Innovation Show) (2010), EXPOCHEM 2011, INTARG 2011, IENA in Norymberga (2010) and ARCHIMEDES in Moscow (2011). e-mail: ; phone: