Barbara JAGUSTYN, Iga PATYNA, Agnieszka SKAWIŃSKA ? Institute for Chemical Processing of Coal (IChPW), Zabrze, Poland

Please cite as: CHEMIK 2013, 67, 6, 552-559

The Polish market of biomass from energy crops and agricultural waste is unstable and strongly dependent on the area of agricultural production land and biomass crops. Import of Palm Kernel Shell may be an additional source of obtaining biomass for energy purposes. Energy and heat manufacturers from all over the world are interested in that combustible material. This paper described an attempt to classify PKS as biomass used for energy purposes. Results from analysing energy characteristics, chemical properties and content biodegradable fraction content in PKS samples tested in IChPW samples of PKS were presented in comparison to characteristics of other types of biomass of agricultural origin.

An increase in using energy from renewable sources (RES) is one of the strategic targets set by the European Union [1, 2]. Increasing prices of conventional fossil fuels, their negative effects on the environment during their use for energy purposes and possible depletion of such resources contribute to the use of renewable fuels. In Poland, plant biomass is said to have the greatest potential among all RES and constitutes the third largest renewable energy source [3]. Pursuant to the Regulation of the Minister of Economy of 18.10.2012, ?biomass is defined as solid or liquid substances of plant or animal origin which undergo biodegradation and are obtained from agricultural and forestry products, wastes and residue as well as from the industry processing such products, and are obtained from remaining wastes which undergo biodegradation, and from grains that fail to meet the qualitative requirements for cereals for intervention buying-in as specified under article 7 of the Commission Regulation (EC) No. 1272/2009 of 11 December 2009 laying down common detailed rules for the implementation of Council Regulation (EC) No 1234/2007 as regards buying-in and selling of agricultural products under public intervention (OJEU L 349 of 29.12.2009, p. 1) and from grains that are not covered by the intervention buying-in? [4]. It is worth paying attention to surplus and wastes from agricultural production while using biomass as fuel. Agro biomass can be used in processes of direct combustion / co-combustion or can be converted into liquid and gaseous fuels. In Poland, imported agricultural biomass is more and more often used as fuel. The President of the Energy Regulatory Office made a decision on the necessity to verify biomass used in production units to avoid any irregularities while qualifying it for biofuels. In accordance with the URE President Communication No. 30/2011 of 4 October 2011, biomass acquired outside the territory of Poland should have documents confirming its origin. Such documents shall be issued by bodies or institutions of the country of biomass origin [5]. Residues from the process of producing Palm Kernel Shell (PKS) from Elaesis guineensis fruit are a type of biomass imported to Poland. Manufacturers of energy and heat all over the world express their interest in this combustible material. According to Schedule 1 to to the URE President Communication of 4 October 2011, PKS should be regarded as a biodegradable material if biomass (biodegradable fraction) content in the tested ash-free dry sample is ?97% [6]. This paper discusses classificability of PKS as biomass used for energy purposes on the basis of the above requirements

Elaeis Guineensis ? African oil palm as an example of agro biomass

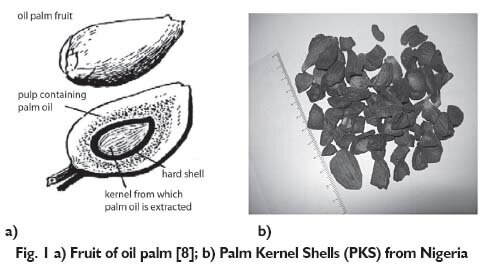

Oil palm, and more precisely Elaeis guineensis Jacq., is a tropical plant belonging to the Arecaceae family. It is widely cultivated in Malaysia, Indonesia as well as in East and Central Africa. Elaeis quineensis Jacq. is the most popular variety of this African palm growing in the territory between Angola and Gambia. It was discovered by Nicholas Jacguin in 1763. This African oil palm can reach the height even up to 30 meters. It starts bearing fruit after a five-year long vegetation period, and its productivity period is 25÷30 years. A palm is able to produce 8÷12 bunches of fruit each year. Fruit bunches weigh from 10 to 25 kg and consist of ca. 1÷3 thousand of reddish fruit, the size of a large plum. They have oily succulent outer layer and a kernel rich in palm oil (Fig. 1) [7, 8]. One-hectare plantation of the African oil palm can yield ca. 10 Mg of fruit annually. This yields ca. 3000 kg of palm oil and 750 kg of seed kernels, including 250 kg of high quality palm kernel oil [9].

Production of palm oil

The production of palm oil dates back to the ancient times. The Egyptians produced palm oil manually by boiling and then squeezing fruit to get red and orange oil. Oil palms are usually cultivated to obtain palm oil used in the food, cosmetic and energy industries [9]. Nowadays, fruit is thermally processed to melt a desirable product, that is, palm oil. Palm oil is extracted from pulp of oil palm fruit and it is most commonly used in the food industry. However, oil from palm seeds is used for obtaining non-food products [7]. A mixture of kernels, leaves and other residues from processing oil palm, such as fibres, empty bunches or shells are used as biomass combusted in power boilers. Trunks of oil palm are used to produce low-quality wood material, such as plywood, millboards or chipboards for producing furniture, doors or floors [10]. Crushed kernel of oil palm fruit, known as Palm Kernel Shell (PKS), has recently contributed to widen a range of applications for agricultural fuel. It can be also applied for producing active carbon [10].

Assessing Palm Kernel Shell (PKS) usability in the energy sector

As it was mentioned above, PKSs can be used in the energy sector to produce green energy providing that they meet specified requirements related to their physical and chemical properties. The Institute for Chemical Processing of Coal (IChPW) conducted tests on Palm Kernel Shells to assess their usability for energy purposes. Analysed samples were from Indonesia, Ivory Coast, Ghana and Nigeria.

Analysis of energy characteristics

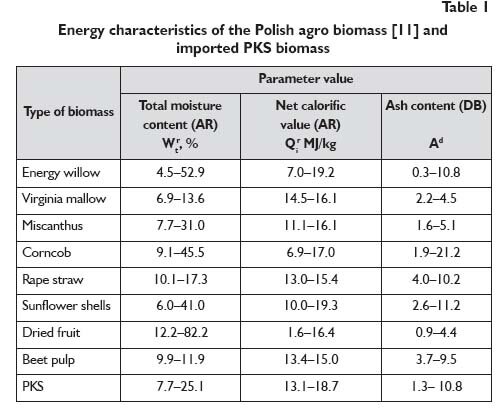

Net calorific value (Qi or qp,net) is a fundamental parameter specifying fuel usability for energy purposes. Net calorific values (AR) of samples analysed in IChPW were within a range from 13.1 MJ/kg to 18.7 MJ/kg. For comparison, net calorific value of the Polish biomass of agricultural origin was from 1.1 MJ/kg to 19.3 MJ/kg [11, 12]

Net calorific value of fuel depends on its combustible components, mineral substances (ash) and moisture content. Moisture content in biomass depends on various factors, such as plant type, vegetation period and atmospheric conditions under which a plant was harvested, transported and stored. Net calorific value of biomass fuel decreases with an increasing moisture content. For Palm Kernel Shell (PKS) samples tested in IChPW, moisture content ranged from 7.7% to 25.1% by mass. For comparison, moisture content in other types of Polish agro biomass was within a range from 4.5% to 82.2% by mass. A course of combustion process is also significantly affected by moisture content. For the same type of biomass with different moisture level, combustion may occur in various parts of combustion chamber. Dry biomass accelerates and stabilises ignition, and wet biomass shifts flame kernel to the upper part of the combustion chamber. It has an impact on heat transfer both in the combustion chamber and in a convection draught through a boiler [13]. The content of mineral substances, frequently defined as ash, is another parameter that influences a decrease in net calorific value of fuels and the course of combustion process. Quantity of ash in biomass depends, among other things, on a part of plant from which it origins (e.g. branches, leaves, fruit, roots), a type of soil and a method of fertilisation. Ash content in PKS samples tested in IChPW was within a range from 1.3% to 10.8% by dry mass. However, a range of ash content in the Polish agro biomass is much wider ? from 0.3% to 21.2% by mass. Changes in net calorific value, moisture and ash content in PKS samples tested in IChPW are illustrated in Figure 2.

Both the quantity of mineral substance (ash) in fuel and its chemical composition are important for the energy sector. In comparison to ash from coal, chemical composition of ash from biomass has significantly higher impact on the formation of low-melt fractions of sediments on the surfaces of power boiler superheaters. It is caused by high content of potassium compounds (from 18.17% to 38.11% by mass) and calcium compounds (6.04% to 48.74% by mass) in the Polish agro biomass [11]. Ash from PKS samples is characterised by lower content of those elements. Silicon compounds are its main components. They reduce the probability of slagging and impurities appearance on the surfaces of power unit heat exchangers [13]. Chemical composition of ash from Palm Kernel Shells for selected samples is presented in Figure 3.

Analysis of chlorine and sulphur content

Chlorine and sulphur content in plants results from their natural presence in soil and applied agrotechnical treatments. A considerable increase in chlorine content in biomass is supposed to be of anthropogenic origin, particularly related to soil contamination or strong salinity of water, for example water from mines or wastewater. Chlorine in plants occurs mainly in a form of Cl- ions usually originating from NaCl and KCl salts. In small amounts, it occurs in an organic form. Sulphur in plant biomass occurs mainly in an organic form, 90% of the total sulphur content is found in aminoacids (cysteine, methionine) [14]. Soil and used mineral fertilisers (e.g. Na2SO4 or elementary sulphur) are sources of inorganic sulphur. It is a macroelement necessary for proper growth and development of plants. Availability of sulphur determines crop yields and improves their quality. Moreover, this element is involved in formation of hydrocarbons and fats and synthesis of chlorophyll and lignin. At the same time, it has an impact on the proper course of photosynthesis [14]. Chlorine and sulphur are undesirable components of fuel because of their corrosive effects. High content of chlorine in fuel results in chloride corrosion. The higher the temperature during combustion in the boiler, the higher the corrosion rate [15]. On the other hand, presence of sulphur in fuels can cause corrosion of power boilers as sediment in a form of sulfates accumulates in heating flues [13, 15]. The tests performed in IChPW demonstrated that chlorine content in Palm Kernel Shell was within a range from less than 0.005% to 0.074% by mass. An average percentage content of this element in PKS was 0.023% by mass, The test results unequivocally indicated that chlorine content in PKS samples was lower than in in other types of agricultural biomass. Low content of sulphur, not exceeding 0.04% by mass, was also observed in the tested Palm Kernel Shell samples. Sulphur content in various types of the Polish biomass used for energy purposes was within a range from less than 0.02% by mass to 0.59% by mass [11]. Table 2 shows compared content of chlorine and sulphur in agro biomass used for energy purposes and in PKS.

Analysis of biodegradable fraction content

The Energy Regulatory Office proposed using a method of selective dissolution for determining the content of biodegradable fraction. This method is based on PN-EN 15440:2011 standard Solid Recovered Fuel ? Methods for determining biomass content developed for fuels produced from wastes [6]. Determination of biodegradable fraction content with a selective dissolution method consists in biomass carbonization using a solution of 78% sulphuric (VI) acid, and then oxidising with 35% hydrogen peroxide. Non-biodegradable fraction and mineral substance form unreacted residue. The content of biodegradable fraction in PKS samples was determined with that method at IChPW. The obtained results from the performed determinations on a dry and ash free basis were at a level from 93.8% to 98.9% by mass. The minimal required content of dry and ash free biomass (biodegradable fraction) in PKS samples specified by the Energy Regulatory Office should equal to ? 97% by mass. If that criterion is not met, fuel cannot be classified as biomass for energy purposes and generated electric power is not eligible for the support system [6]. That criterion was not satisfied by 3 out of 14 analysed PKS samples. Besides the method of selective dissolution, PN-EN 15440:2011 standard accepts the method of determining biomass content with 14C method. Therefore, comparative tests employing those two methods were performed. The test using the 14C method was performed in the Radiocarbon Laboratory at the Institute of Physics at at the Silesian University of Technology in Gliwice. Concentration of 14C was determined in selected PKS samples using the LSC (Liquid Scintillation Counting) technique. Compared mass content of biodegradable fraction in PKS samples determined by both methods using a classification criterion specified by URE is illustrated in Figure 4.

The comparison of results from determining the content of biodegradable fraction (biomass) in PKS samples showed that lower values were obtained from the selective dissolution method than from the 14C method. An alternative method verified the low content of biodegradable fraction in PKS samples, which was determined by the selective dissolution method at the level of ca. 94%. The 14C method demonstrated that the level of biodegradable fraction content in those samples satisfied URE requirements (?97%). Lower values determined by the selective dissolution method could be caused by the presence of organic components, hardly dissolved in sulphuric (VI) acid and hydrogen peroxide, in the analysed biomass. Despite the risk of obtaining a lower value from determining the biodegradable fraction content in some cases, this method is recommended for energy manufacturers. The method of selective dissolution can be commonly applied in the majority of industrial laboratories because of its availability and low costs of measurement and testing equipment. However, in case of employing the 14C method, a laboratory requires expensive and professional measurement and testing equipment. For the energy sector, analysis time is also important. Nowadays, the 14C method needs from 8 to 12 weeks, so the analysis time is even 3-fold greater than the analysis conducted with the selective dissolution method.

Conclusions

The Polish market of biomass from energy crops and agricultural waste is unstable and strongly dependent on the area of agricultural production land and biomass crops. Import of Palm Kernel Shell may be an additional source of obtaining biomass for energy purposes. Palm Kernel Shells (PKS) are characterised by relatively low moisture and ash content which affects their higher net calorific values in comparison to other types of plant biomass. Low content of sulphur, chlorine and ash components forming sediment is an advantage of the analysed biomass. This has a positive impact on the operation of power boilers and reduces the probability of hightemperature corrosion. The tests performed in the Institute of Chemical Processing of Coal have showed that the biodegradable fraction content determined with the selective dissolution method in imported Palm Kernel Shells is usually higher than the minimum level of 97% by mass required by URE. If biodegradable fraction content determined with the selective dissolution method fails to meet that criterion, then the obtained result can be additionally verified using the 14C method. Lower content of biomass in PKS determined with the selective dissolution method should not be considered as lower biodegradability of that material. It is caused by the presence of organic components that do not dissolve. Taking into account the suitable equipment availability and shorter analysis time, commercial laboratories and power engineering companies can use that method for determining the content of biodegradable fraction in biomass.

Literature

1. Gąsiorowska E., Piekacz J., Surma T.: Pakiet klimatyczno-energetyczny jako strategia zrównoważonego rozwoju gospodarki europejskiej. Energetyka 2008, 551?561.

2. Ludwicka A., Grzybek A.: Bilans biomasy rolnej (słomy) na potrzeby energetyki. Problemy Inżynierii Rolniczej 2010, 2, 101?111.

3. Gutowska A.E.: Biomasa jako surowiec energetyczny, Energia odnawialna, jak z niej korzystać? Podlaska Fundacja Rozwoju Regionalnego, Białystok, 2007.

4. Rozporządzenie Ministra Gospodarki z dnia 18 października 2012 r. w sprawie szczegółowego zakresu obowiązków uzyskania i przedstawienia do umorzenia świadectw pochodzenia, uiszczenia opłaty zastępczej, zakupu energii elektrycznej i ciepła wytworzonych w odnawialnych źródłach energii oraz obowiązku potwierdzania danych dotyczących ilości energii elektrycznej wytworzonej w odnawialnym źródle energii (Dz. U. 2012, nr 0, poz. 122).

5. Informacja nr 30/2011 w sprawie kwalifikacji biomasy na cele energetyczne Prezesa Urzędu Regulacji Energetyki z dnia z dnia 4 października 2011 r. http://www.ure.gov.pl/portal/pl/424/4306/Prad_z_palmy_olejowca_Prezes_ URE_o_kwalifikacji_biomasy_na_cele_energetyczne.html

6. Załącznik nr 1 do Informacji nr 30/2011 w sprawie kwalifikacji biomasy na cele energetyczne pozostałości z procesu uzyskiwania oleju palmowego z palmy olejowca gwinejskiego (niezależnie od postaci handlowej ? łupina i makuch z palmy olejowca gwinejskiego) z dnia 4 października 2011 r. http://www.ure.gov.pl/portal/pl/424/4306/Prad_z_palmy_olejowca_Prezes_

URE_kwalifikacji_biomasy_na_cele_energetyczne.html

7. Górecka A.: Produkcja oleju palmowego a odpowiedzialność za naturalne środowisko. Przemysł spożywczy 2011, 65, 28?30.

8. The oil palm. Institut africain pour le développement économique et social. FAO Economic and Social Development Series, nr 3/24.

9. Rohwer J.: Atlas roślin tropikalnych. Horyzont, Warszawa, 2002. http:// www.fao.org/docrep/006/T0309E/T0309E00.HTM

10. Kabbashi, Naserelden and Jamal Ibrahim, Daoud and Jami: Statistical analysis for malachite green removal using palm-kernel-shell-activated carbon. Australian Journal of Basic and Applied Sciences, Saedi 2011, 5(1).

11. Jagustyn B., Bątorek-Giesa N., Wilk B.: Właściwości fizykochemiczne biomasy wykorzystywanej do celów energetycznych. Materiały konferencyjne Ekoenergetyka ? Biogaz i syngaz. Ekoenergetyka ? zagadnienia technologii, ochrony środowiska i ekonomiki 2010, 144?145.

12. Kozłowski S., Lutyński A., Zielewicz W.: Określanie wartości energetycznej Sorghum saccharatum L. Moench, Zea mays L. i Malva verticillata L. Łąkarstwo w Polsce. Polskie Towarzystwo Łąkarskie, Poznań, 2007, 10, 1.

13. Ściążko M., Sobolewski A., Zuwała J.: Przewodnik Metodyczny Procedury bilansowania i rozliczania energii wytwarzanej w procesach współspalania. IChPW, Warszawa ? Zabrze, 2007.

14. Kaczor A., Zuzańska J.: Znaczenie siarki w rolnictwie. Chemia ? Dydaktyka ? Ekologia ? Metrologia 2009, 14, 1?2, 69.

15. Król D., Łach J., Poskrobko S.: O niektórych problemach związanych z wykorzystaniem biomasy nieleśnej w energetyce. Energetyka 2010, 53?62.

Barbara JAGUSTYN ? M.Sc., graduated from the Faculty of Chemical Technology and Engineering at the Silesian University of Technology in Gliwice in 1994. Specialisation ? chemical technology of coal and crude oil. Since 1994, she has been working for the Institute for Chemical Processing of Coal in Zabrze. She specialises in issues related to analyses of solid fuels, biomass, solid recovered fuels and combustion wastes. She is a technical expert at the Proficiency Testing Centre at the Institute of Chemical Processing of Coal. e-mail: ; phone: +48 32 2710041, Ext 221

Iga PATYNA ? M.Sc, graduated from the Faculty of Chemistry at the Silesian University of Technology in Gliwice in 2011. She is currently working as an engineer for the Institute for Chemical Processing of Coal in Zabrze. Research interests: energy characteristics of alternative fuels, mercury porosimetry e-mail: ; phone: , Ext 206

Agnieszka SKAWIŃSKA ? M.Sc., graduated from the Faculty of Biology at the University of Silesia in 2005. She is currently working as a senior specialist in engineering and technology in the Institute for Chemical Processing of Coal in Zabrze. Research interests: application of biomass for energy purposes, cultivating and processing micro-algal biomass. e-mail: ; phone: , Ext 206